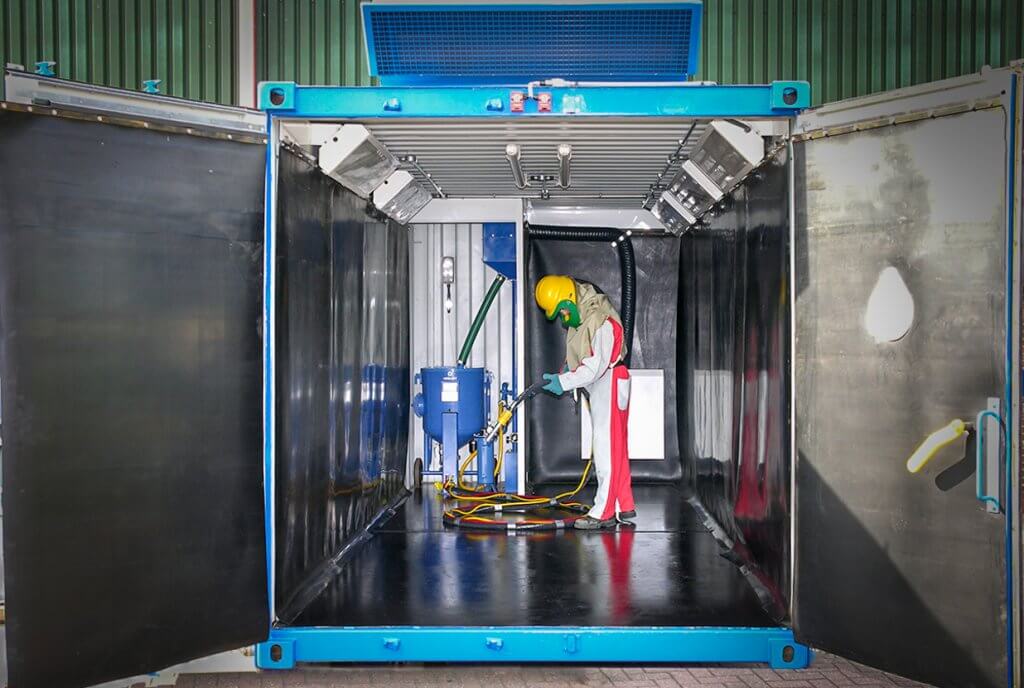

When you work with large equipment, blast rooms are a great investment for cleaning, stripping, and preparing surfaces for coating.

Airblast AFC designs and engineers innovative blast rooms that increase functionality and versatility when it comes to surface preparation tasks. While blasting is a highly efficient way of performing these operations, there are many ways in which you can increase your safety and efficiency while blasting.

What is Shot Blasting?

Blasting is the process whereby abrasive particles are ejected at high speed to strip surfaces for the purposes of cleaning them or preparing them for coating. Common blasting media include glass beads, aluminum oxide, acrylic, pumice, silicon carbide, steel, and walnut shells. Blasting media is inexpensive and requires little effort, but the following tips will help you to achieve a successful result.

Prepare the Area

It is crucial that you sufficiently prepare the area before blasting. Airblast AFC strongly recommends that you clean the surface first using a power washer. This ensures that there is no debris that will interfere with the blasting process.

Control the Temperature and Humidity

It is essential that you keep temperatures and humidity levels low when blasting so that you reduce the amount of moisture in the air. While this may be challenging in larger blast rooms, it will ensure that your coating application and drying time is not hindered.

Use Proper Techniques

While blasting, the pressure of the media blast can have an effect on your comfort and safety. Ensure that the blast nozzle is placed at the correct angle for the pressure of the media as well as the placement of the surface. When stripping surfaces, it’s often advisable to blast from a diagonal angle, as if using a scraper. This strips surfaces more effectively and avoids shattering the media. By contrast, blasting directly at a hard surface causes the abrasive to shatter, which means it cannot be recycled and reused by the system and must be disposed of. This not only creates more dust, which hampers visibility, but also uses abrasive more quickly, which increases costs.